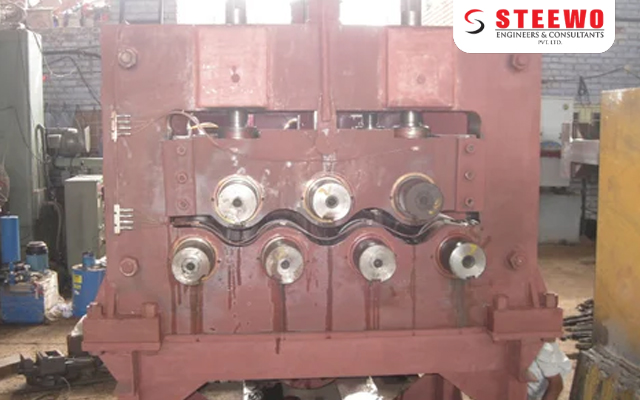

Straightening Roller MachineSteewo

Steewo Engineers is renowned as one of the most reputed straightening roller machine manufacturers. These automatically operated machines are simple to install and use. We manufacture the purest and top-quality roller straightening machine for you. We promise to give you the best at the lowest cost. This is the explanation for why you need to have faith in our straightening equipment. These machines are capable of straightening Angles, Channels, Grinders, and all other hot-rolled products. Our machines exceed all of your expectations and are incredibly efficient. All parts of those roller straightening machines are made using the highest grade materials and are entirely constructed of pure steel.

The body of these rolling mill section straightening machines, which can support the gears needed to power the rolls, is strengthened and enhanced by the use of premium steel plates in their manufacturing. The steel plates used are of adequate thickness with the outer body lining of the same plates. Additionally, the reduction gearbox is mounted to the machine’s frame.

Steewo Engineers is the best leading straightening roller machine manufacturers and exporters in India. These roller straightening machines are easy to operate and small in size. The ideal uses for our multi roll straightening machines are to straighten ferrous or nonferrous metal goods such as angles, rounds, channels, beams, rebars, and so on that have been curled, outstretched, or driven out. Our machines have a distinctive design that sets them apart from the competition. Their compact design makes them easier to use.

Leading Straightening Rolling Machine Manufacturers and Suppliers in India- Steewo Engineers

We are known for the outstanding functionality of our machines. Our flawless selection of equipment guarantees total customer satisfaction with both performance and quality. Our roller straightening machines work well in a variety of applications, including cutting thick billet, hot bars, plate scraps, and TMT bundles, among others. We offer straightening rolling machines with screen-down mechanisms that are heavy-duty worm gear types. These are suitable for joists up to 500 mm Channels up to 400 mm Angles 200 x 200 mm. These are suitable for joists up to 500 mm Channels up to 400 mm Angles 200 x 200 mm. These machines are well-known across the world for their minimal maintenance requirements, maximum utility, and dimensional accuracy. They are available in various capacities and roll centers.

Features:

- Fully automatic steel-bar straightening & cutting machine.

- Hi-speed accurate straightening.

- Automatic cutting with adjustable length.

- High operational fluency.

- Low power consumption.

- The machine comes with a suitable ratio reduction gearbox installed.

- Handy to operate and control the machine ensuring safety whilst in use.

- Runs on an excellent power motor.

- Cost-effective.

- Unique & sleek in design.

- In compliance with the industrial standards.

- Smooth straightening & cutting motion.

What is the Need for a Straightening Roller Machine?

Steewo Engineers manufactures the high-quality and purest straightening rolling mill machine for you. We promise to give you the finest at a reasonable price. These machines are in charge of straightening grinders, angles, channels, and other similar hot-rolled products. Our machines are highly efficient and withstand all your expectations from them. Since these straightening roller machines are entirely made of pure steel, only the highest quality materials are used in their manufacturing. Steewo Engineers not only manufactures these mild steel roll straightening machines but is also amongst the leading exporters of them. We provide the fastest possible product delivery to our customers and ship our machines all over the world.

A straightening roller machine effectively realigns hot-rolled material to meet exacting quality standards by putting it under controlled pressure and making precise changes. This process not only enhances the overall aesthetics of the final product but also ensures uniformity in mechanical properties, contributing to the production of high-quality materials that meet the exacting specifications of diverse industries.

Contact us