High-Quality Alloy Steel Mill Manufacturing Company in India Steewo

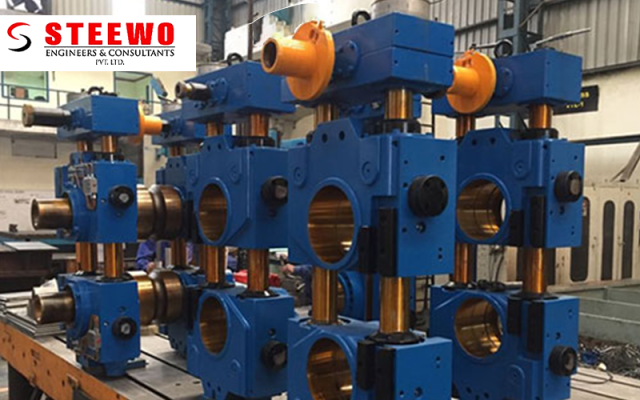

Steewo Engineers produces Alloy steel mill and is the first manufacturer in India that has supplied Alloy mills with HV stands. For your unique steel demands, we design, build, and manufacture Allot steel mills. We offer cost-effective Alloys Mill plants with great productivity. We create unique solutions just for you, no matter where you are in the world, based on the quality of special steel and the manufacturing volume that you need. As a premier Alloy steel rolling mill plant manufacturers and suppliers company in India to UK, US, UAE, Canada, Afghanistan, Australia, China, Iran, Iraq, Kuwait, Oman, Qatar, Russia, Saudi Arabia, Turkey, Uzbekistan, Yemen, Europe and many more other countries, we take immense pride in delivering cutting-edge solutions for the steel industry.

Steewo Engineers produces Alloy steel mill and is the first manufacturer in India that has supplied Alloy mills with HV stands. For your unique steel demands, we design, build, and manufacture Allot steel mills. We offer cost-effective Alloys Mill plants with great productivity. We create unique solutions just for you, no matter where you are in the world, based on the quality of special steel and the manufacturing volume that you need. As a premier Alloy steel rolling mill plant manufacturers and suppliers company in India to UK, US, UAE, Canada, Afghanistan, Australia, China, Iran, Iraq, Kuwait, Oman, Qatar, Russia, Saudi Arabia, Turkey, Uzbekistan, Yemen, Europe and many more other countries, we take immense pride in delivering cutting-edge solutions for the steel industry.

We distinguish ourselves as industry leaders in alloy steel production due to our cutting-edge facilities and highly qualified staff. As a customer-centric Alloy steel rolling mill manufacturers in India and more than 20+ countries, we offer a comprehensive range of products, meeting the diverse needs of our customers. Our products, which range from sheets, plates, pipes, and tubes to bars and rods, are known for their dependability and efficiency. As the first choice of those looking for premium alloy steel solutions, we maintain a global perspective and offer our knowledge to clients all over the world.

Steewo Engineers is the top high capacity Alloy steel mill manufacturers and suppliers company in India. We have a global presence and are prepared to meet the specific needs of any industry, solidifying our position as a leading special Alloy steel rolling mill products supplier and manufacturers company in the market. Dedicated to excellence, our company specializes in offering high quality Alloy steel mill plant and machinery.

Alloy Steel Rolling Manufacturing Process

The production process of alloy steel rolling mills involves a sophisticated interplay between metallurgical knowledge, state-of-the-art technology, and precision engineering. The meticulous selection of raw materials is the foundation of our business, assuring that the alloy steel’s unique composition corresponds with the intended product features. To obtain the perfect chemical composition, the raw materials—which frequently include iron, carbon, and alloying elements—go through a rigorous testing and blending process.

The production process of alloy steel rolling mills involves a sophisticated interplay between metallurgical knowledge, state-of-the-art technology, and precision engineering. The meticulous selection of raw materials is the foundation of our business, assuring that the alloy steel’s unique composition corresponds with the intended product features. To obtain the perfect chemical composition, the raw materials—which frequently include iron, carbon, and alloying elements—go through a rigorous testing and blending process.

The primary melting furnace is where the raw ingredients are converted into molten metal after they have been processed. To form the first shapes that will be further treated, this molten metal is then continually cast into billets or cast into ingots. The next critical phase involves the hot rolling process. To obtain the appropriate shape, size, and mechanical qualities, the heated billets or alloys are put through a sequence of rolling mills where they are subjected to controlled deformation. This process imparts strength and uniformity to the Alloy steel, enhancing its structural integrity. Clients trust us as their preferred high strength Alloy steel mill plant company in India due to our unwavering dedication to delivering top-tier products.

Our Product Range

Steewo Engineers is the best manufacturers and suppliers of Alloy steel rolling mill in India and many Abroad Countries such as United States, United Kingdom, Canada, Afghanistan, Australia, China, Iran, Iraq, Kuwait, Oman, Qatar, Russia, Saudi Arabia, Turkey, United Arab Emirates, Uzbekistan, Yemen and Europe, our expertise lies in producing an extensive array of alloy steel goods that are customized to fulfill the unique requirements of different sectors. Our product portfolio includes:

- Alloy Steel Bars and Rods: Designed for durability, versatility, and strength, our Alloy steel bars and rods find applications in the automotive, construction, and machinery industries.

- Alloy Steel Sheets and Plates: Exquisitely designed to satisfy the rigorous demands of many uses, our sheets and plates provide remarkable durability and resistance to wear and tear.

- Alloy Steel Pipes and Tubes: Whether for industrial or structural purposes, Our alloy steel tubes and pipes are renowned for their great performance, dependability, and corrosion resistance .

- Custom Alloy Steel Solutions: We collaborate closely with our clients to create specialized alloy steel solutions that meet their specific needs. Our engineering expertise allows us to create products that enhance efficiency and productivity.

Why Choose Us For Alloy Steel Rolling

Choosing the appropriate partner for alloy steel rolling is an important choice that will have a big impact on the effectiveness, success, and quality of your projects. At Alloy steel mill facility, we pride ourselves on being the preferred choice for a myriad of reasons:

- Expertise and Experience: We bring an abundance of knowledge to alloy steel rolling, supported by years of industry experience and a team of seasoned specialists. Our expertise enables us to manage challenging projects and provide solutions that meet the particular needs of various sectors.

- Cutting-Edge Technology: Our facility, which is outfitted with the most advanced machinery and technology available, guarantees accuracy and effectiveness in each roll. We stay at the forefront of technological advancements, enabling us to offer Alloy steel rolling solutions that meet the highest standards of performance and quality.

- Quality Assurance: Our procedures are all focused on quality, starting with the raw material selection and ending with the final inspection of the rolled products. Our alloy steel rolling constantly delivers excellent outcomes because of stringent testing, adherence to global standards, and a dedication to quality.

- Timely Deliveries: We place a high value on timely delivery and effective production schedules since we recognize how important schedules are to the completion of projects. Our streamlined processes and logistical expertise ensure that your Alloy steel rolling needs are met promptly.

FAQ's of Alloy Steel Rolling Mill

What are Alloy steel rolling mills?

Alloy steel is a kind of steel that has different amounts of extra elements added to it to improve its strength, hardness, and resistance to corrosion, such as chromium, nickel, manganese, or other alloying elements.

What is the role of an alloy steel mill in the manufacturing process?

A mill that processes raw materials, such as iron ore and alloying components, to create alloy steel is called an alloy steel mill. The mill produces the required alloy steel products by using procedures including melting, casting, rolling, and heat treatment.

What are the common applications of alloy steel?

Many industries, including the automotive, aerospace, construction, and manufacturing sectors, employ alloy steel extensively. Manufacturing parts for equipment, motors, gears, tools, and structural components are among the common uses.

What are the advantages of using alloy steel in industrial applications?

Alloy steel offers advantages such as wear resistance, increased strength, hardness, and corrosion resistance compared to carbon steel.

Contact us