Roller Table Manufacturers and Suppliers from Jaipur, India Steewo

Steewo Engineers is the leading Roller Table manufacturer in India, we are a reputed exporter & manufacturer of roller tables utilized in rolling mills to handle the channel, flat, angle & round, etc. These roller tables are useful to extend the production capacity of steel rolling mills and reduce manpower. Section TMT Rolling Mills are mostly equipped with Roller Conveyors or Roller Tables. Instead, conveyors are employed everywhere these days to reduce worker effort. It must move ingots or billets to different furnaces, feed in raw materials from the furnace to the rough mill, and use a cooling bed conveyor to move the finished product to the shearing machine for cutting at the designated length.

Steewo Engineers is the leading Roller Table manufacturer in India, we are a reputed exporter & manufacturer of roller tables utilized in rolling mills to handle the channel, flat, angle & round, etc. These roller tables are useful to extend the production capacity of steel rolling mills and reduce manpower. Section TMT Rolling Mills are mostly equipped with Roller Conveyors or Roller Tables. Instead, conveyors are employed everywhere these days to reduce worker effort. It must move ingots or billets to different furnaces, feed in raw materials from the furnace to the rough mill, and use a cooling bed conveyor to move the finished product to the shearing machine for cutting at the designated length.

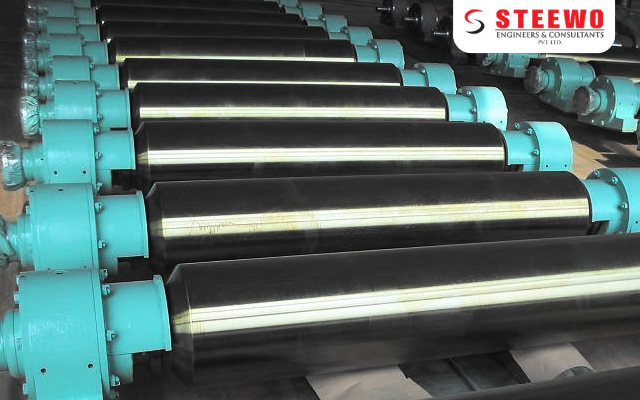

Steewo Engineers, as the prominent Roller Table manufacturers and Roller Table exporters, take pride in producing the best quality roller conveyors in the country. Our roller table are world-renowned for their reliability and durability. Their long lifespan and superior performance have made them a popular choice for large-scale steel rolling mill projects worldwide. The roller conveyor/table, which is utilized to move hot or cold material from one station or stand to another, is one of the mechanical material handling tools that we offer.

These are steel fabricated structures and consist of fully machined seamless Alloy steel round/ seamless pipe, steel structure, chain sprockets, v-belt pulley, bearings & bearing blocks complete with a lubrication system. Depending on the need and suitability, they are powered by gearboxes, motors with chains and chain sprockets, or motors and pulleys with v-belts.

Steewo Engineers- Exporter & Supplier of Roller Table

Steewo Engineers manufactures the most competitive range of Roller table that are used in rolling mills. They move the ingot or billet to the charging furnace, feed it into the roughing mill, and use a cooling bed conveyor to move the completed product to the shearing machine for the appropriate length of cutting. The hot rolling roller table plays a crucial role in facilitating the movement of the metal stock through the rolling mills.

The standard configuration of a hot rolling roller table is a sequence of revolving, parallel rollers spaced and oriented uniformly along the table’s length. The metal stock is supported and directed as it travels along the table and is positioned on top of the The metal stock is propelled forward by the rollers rotation, which guarantees a steady and seamless flow through the rolling mills. The roller table can be straight or curved, depending on the layout and configuration of the rolling mill.

In addition to supporting the metal stock, hot rolling roller tables can have elements like water sprays or cooling jets to help regulate the metal’s temperature while it’s being rolled. These cooling mechanisms assist prevent overheating and ensure the quality and integrity of the rolled products.

Manufacturing Process

Being the industry-leading roller table manufacturers, we take pride in our manufacturing process. Across numerous industries worldwide, our roller conveyors are in widespread. We ensure that every single roller table is designed and built with an unsparing eye for detail. Every roller conveyor that comes out of our plant will be of the highest quality available for roller conveyors. We can accomplish this because of the cutting-edge equipment we utilize to make each Roller Table. We ensure that we listen to the demands of our customers. We tailor our roller conveyors to our client’s requirements and their specific projects.

Features:

- V-Belt/ Pulley Drive.

- Chain Driven.

- Quality Bearings for Smooth Running.

- Seamless Pipe with Tested Shafts.

- Quality Bearings.

Contact us